Enhancing Drone Body Manufacturing Effectivity with CNC Machining Methods

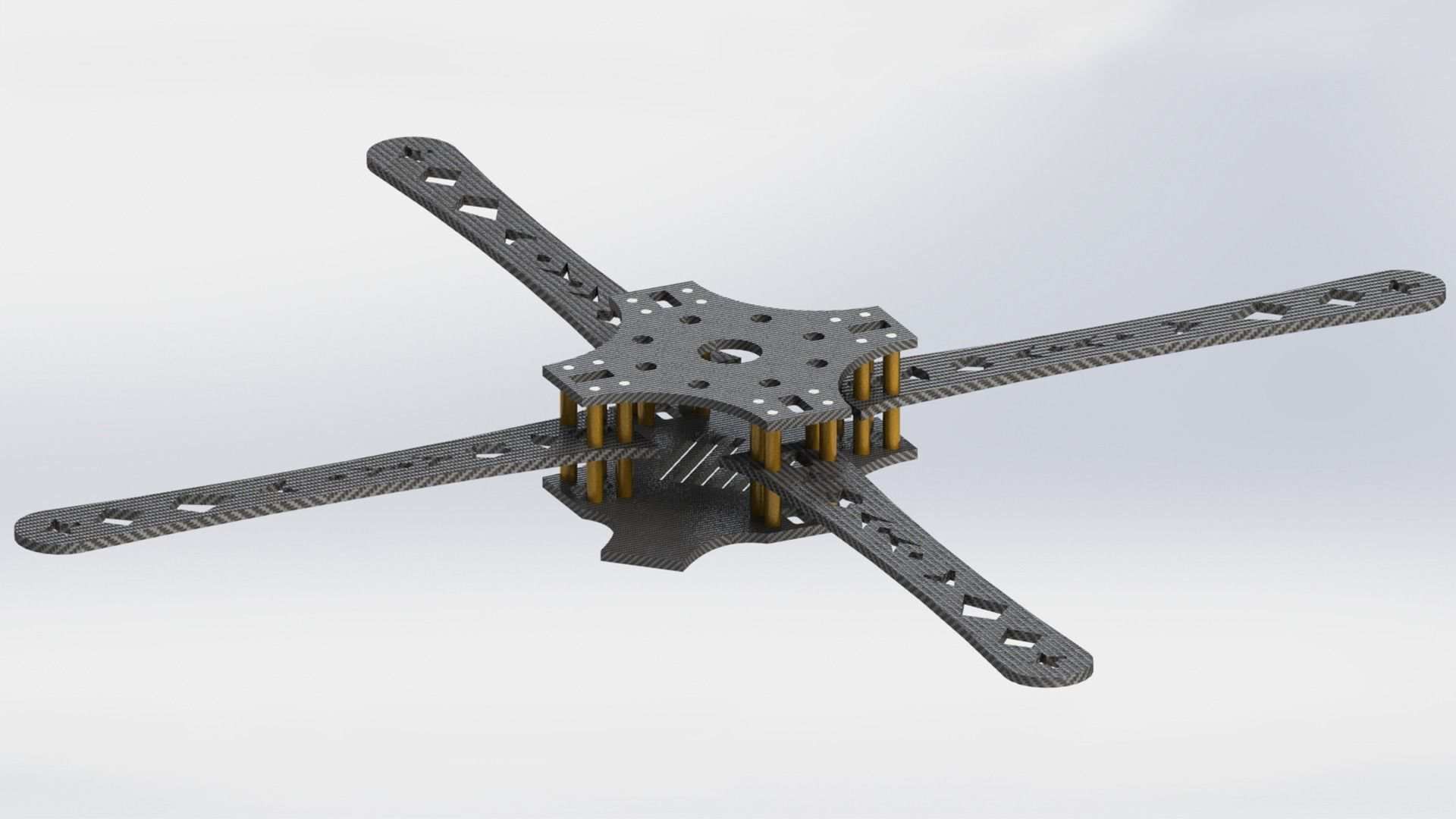

As the recognition of drone expertise continues to soar, the demand for high-quality, environment friendly, and sturdy drone frames has by no means been higher. Amongst numerous manufacturing methods, CNC machining stands out as a revolutionary technique that considerably enhances the manufacturing effectivity of drone frames.

This text delves into the quite a few advantages of CNC machining, one of the best supplies for drone frames, and optimization methods tailor-made for each freestyle and racing frames. By understanding these parts, producers can elevate their manufacturing processes and meet the evolving wants of drone pilots.

What are the Advantages of Utilizing CNC Machining for Drone Body Manufacturing?

![]()

How Does CNC Machining Enhance Body Sturdiness?

CNC machining is famend for its precision and reliability, two crucial components that improve the sturdiness of drone frames. By using superior software program that interprets intricate designs into machine instructions, CNC machines can produce frames that stand up to the trials of flight.

As an illustration, a drone body crafted from carbon fiber via CNC machining can resist stress and influence, thereby prolonging its life span. This sturdiness is paramount for FPV pilots who have interaction in high-speed racing or freestyle maneuvers, because the frames are sometimes subjected to harsh situations.

The constant high quality achieved via CNC machining mitigates the chance of defects, guaranteeing that each drone body can endure difficult environments whereas sustaining structural integrity.

Can CNC Machining Scale back Manufacturing Prices for Quadcopter Frames?

One of the vital benefits of CNC machining is its potential to scale back manufacturing prices. Conventional manufacturing strategies usually contain intensive handbook labor and longer lead instances, which might inflate the general bills.

In distinction, CNC machining automates a lot of the manufacturing course of, permitting for faster turnaround instances and minimizing labor prices. Consequently, producers can produce a number of drone frames concurrently, additional driving down prices.

Moreover, the precision of CNC machining minimizes waste materials, resulting in extra economical use of sources. This effectivity is especially advantageous for companies seeking to scale their manufacturing of racing frames, freestyle frames, and even micro frames for brand spanking new entrants into the drone interest.

What Are the Precision Benefits of CNC Machining in Drone Body Manufacturing?

The precision supplied by CNC machining is unparalleled, particularly within the realm of drone body manufacturing. With the aptitude to realize tolerances as tight as 0.001 inches, CNC machines can create intricate designs that improve the efficiency of drone frames.

This degree of precision is essential for parts resembling motor mounts and electronics placements, the place even minor discrepancies can result in efficiency points. As an illustration, a well-designed FPV drone body package can considerably enhance the responsiveness and agility of a quadcopter, in the end offering a superior flying expertise.

The flexibility to duplicate designs precisely additionally implies that producers can guarantee consistency throughout all produced frames, a necessary issue for sustaining high quality requirements in racing and freestyle functions.

Which Supplies Are Greatest for CNC Machined Drone Frames?

![]()

Why is Carbon Fiber Advisable for FPV Racing Frames?

Carbon fiber is commonly touted as the perfect materials for FPV racing frames resulting from its exceptional strength-to-weight ratio. When CNC machined, carbon fiber frames might be each light-weight and extremely sturdy, making them excellent for racing functions the place pace and agility are paramount.

The light-weight nature of carbon fiber permits for faster acceleration and enhanced maneuverability, important for aggressive racing eventualities.

Moreover, carbon fiber’s capacity to soak up vibrations contributes to smoother flight traits, thereby enhancing the general pilot expertise. Many racing lovers flip to manufacturers like NewBeeDrone and Axisflying for his or her carbon fiber racing frames, searching for one of the best mixture of efficiency and sturdiness.

How Do Totally different Supplies Have an effect on the Weight and Efficiency of a Quadcopter Body?

The selection of fabric for drone frames considerably impacts weight and efficiency, that are crucial components for pilots. As an illustration, aluminum frames are recognized for his or her robustness and rigidity however might be heavier in comparison with carbon fiber alternate options. This weight can hinder the agility of a quadcopter, particularly in racing eventualities the place split-second selections matter.

Then again, lighter supplies result in sooner flight speeds however might compromise sturdiness. Producers usually experiment with hybrid designs, combining supplies to realize optimum weight and resilience. When crafting frames for FPV or freestyle racing, understanding the trade-offs between weight and efficiency is important for producing a profitable drone body.

What Are the Professionals and Cons of Utilizing Aluminum vs. Carbon Fiber for Drone Frames?

When evaluating aluminum and carbon fiber for drone frames, it’s important to grasp the distinct benefits and downsides of every materials. Aluminum frames are typically extra reasonably priced and simpler to fabricate, making them a preferred selection for entry-level drone kits, such because the Mobula7 whoop body package or the Pavo25 v2 brushless whoop body.

Nonetheless, whereas they provide respectable sturdiness, they are often extra vulnerable to bending and fatigue over time. Conversely, carbon fiber frames present superior energy and light-weight traits, enhancing flight efficiency considerably. The draw back, nonetheless, is that carbon fiber might be costlier, making it much less accessible for informal hobbyists.

Finally, the selection between aluminum and carbon fiber ought to align with a pilot’s particular wants, funds, and supposed use.

How Can You Optimize CNC Machining Methods for Freestyle Drone Frames?

What Design Options Ought to Be Thought-about for a Freestyle Body Package?

Designing a freestyle body package requires cautious consideration of varied options that improve efficiency and pilot expertise. A squashed X design, which permits for higher aerodynamics and stability throughout flight, is commonly favored by freestyle pilots.

Moreover, incorporating modular parts facilitates simpler repairs and upgrades, enabling pilots to customise their drone frames in keeping with their preferences. Mounting choices for electronics, such because the VTX and HD O3 models, ought to be built-in seamlessly into the body design to keep up a clear aesthetic whereas guaranteeing performance.

These design options not solely elevate the efficiency of freestyle drones but additionally improve the general person expertise for pilots.

How Does CNC Machining Improve the Aerodynamics of FPV Drone Frames?

CNC machining performs a vital function in enhancing the aerodynamics of FPV drone frames by permitting for exact shaping and contouring. Frames might be designed with particular airfoil profiles that scale back drag, enabling sooner speeds and improved dealing with.

This aerodynamic effectivity is especially essential for freestyle drones, which frequently carry out complicated maneuvers requiring fast modifications in course and pace. The flexibility to create light-weight but structurally sound designs via CNC machining additional contributes to the general agility of the drone.

Pilots seeking to elevate their FPV expertise can profit from frames that prioritize aerodynamic traits, guaranteeing that they’ll execute their maneuvers with precision and confidence.

What Customization Choices Are Accessible for CNC Machined Freestyle Frames?

Customization is a major benefit when using CNC machining for freestyle frames. Producers can supply numerous choices, from body coloration decisions to particular mounting configurations tailor-made to particular person pilot preferences. As an illustration, pilots can select the perfect coloration for his or her freestyle FPV body, permitting for personalised aesthetics.

Moreover, customization can prolong to the mixing of particular parts, resembling motor mounts designed for various motor sizes or placements for extra equipment. This degree of personalization not solely enhances the person expertise but additionally empowers pilots to create a drone that really displays their fashion and efficiency wants.

What CNC Machining Methods Are Greatest for Racing Drone Frames?

How Can You Use CNC Machining to Create Light-weight Racing Frames?

Creating light-weight racing frames via CNC machining entails using numerous methods that decrease materials utilization with out sacrificing energy. One efficient method is to make the most of superior software program to optimize design geometries, enabling producers to provide intricate cutouts that scale back weight whereas sustaining structural integrity.

Moreover, choosing the precise supplies, resembling high-grade carbon fiber, permits for the creation of frames which can be each light-weight and sturdy. Racing frames that incorporate these methods can present a aggressive edge, as each ounce counts within the fast-paced world of FPV racing.

What Are the Key Concerns for Designing a Racing Body with CNC Know-how?

When designing a racing body utilizing CNC expertise, a number of key concerns have to be taken into consideration. At first is the steadiness between weight and energy; a well-designed racing body ought to be light-weight sufficient to facilitate pace but sturdy sufficient to face up to the trials of aggressive racing.

The body’s geometry should even be optimized for aerodynamics, guaranteeing that airflow is managed successfully throughout high-speed maneuvers. Moreover, accessibility for electronics and ease of upkeep are essential, as pilots usually must make fast changes between races.

By specializing in these concerns, producers can create racing frames that not solely carry out exceptionally but additionally attraction to the aggressive FPV group.

How Does the CNC Machining Course of Affect the Velocity of a Drone?

The CNC machining course of immediately influences the pace of a drone by affecting its general weight, aerodynamics, and structural integrity. Lighter frames made potential via exact machining, can obtain greater speeds because of the decreased inertia that enables for faster acceleration.

Moreover, the aerodynamically optimized designs produced by CNC machines scale back drag, enhancing the drone’s capacity to chop via the air effectively. A well-crafted racing drone body, resembling these from manufacturers like ImpulseRC Echo and Five33, showcases how CNC machining can create aggressive benefits.

On this manner, expert producers can leverage CNC expertise to provide frames that push the boundaries of pace and efficiency.

How Do You Select the Proper CNC Machined Body for Your Drone?

What Elements Ought to You Take into account When Selecting a Quadcopter Body?

Deciding on the precise quadcopter body entails a number of components that may considerably influence flight efficiency and general person expertise. First, take into account the body’s dimension; bigger frames might supply stability however might be heavier, whereas smaller frames improve agility however might compromise sturdiness.

Moreover, the supposed use of the drone—be it for racing, freestyle, or cinematic functions—ought to information your selection. For instance, a racing body should prioritize light-weight design and aerodynamics, whereas a cinematic body would possibly give attention to stability and payload capability.

Evaluating these components ensures that pilots can select a body that aligns with their particular flying fashion and targets.

Easy methods to Choose the Proper Dimension for Your FPV Drone Body Package?

Choosing the proper dimension on your FPV drone body package is essential for optimizing efficiency and guaranteeing compatibility with different parts. The dimensions of the body ought to correlate with the kind of flying you propose to do; for example, racing frames usually fall throughout the 3.5-inch to 5-inch vary to steadiness pace and maneuverability.

In the meantime, micro frames designed for FPV whoop flying, such because the Mobula7, could also be as small as 65mm, making them supreme for indoor flying. Moreover, take into account the scale of the motors and electronics you propose to make use of, as these will affect your body choice. By fastidiously assessing these points, pilots can choose a body dimension that most closely fits their flying wants.

What Are the Greatest Practices for Matching Electronics to Your CNC Machined Body?

Matching electronics to your CNC machined body is important to make sure optimum efficiency and a seamless flying expertise. Begin by contemplating the body’s design and structure; for instance, frames with particular mount designs might dictate the kind of motors or VTX models that can be utilized.

Moreover, be sure that the burden of the electronics aligns with the body’s capability to keep up steadiness and stability throughout flight. It’s additionally essential to think about the facility necessities of your motors and the flight controller, guaranteeing that the battery can ship satisfactory energy with out including extra weight.

Following these finest practices helps to create a well-integrated drone system that performs at its finest.

Learn Extra: What’s CNC Fixture: Sorts, Functions, and Workholding Suggestions

Benefits of XMAKE as a CNC machining provider

XMAKE stands out as a number one CNC machining provider for a number of causes. First, XMAKE makes use of state-of-the-art CNC machines, together with multi-axis and high-speed machining facilities, which guarantee excessive precision and effectivity in producing drone frames.

Second, XMAKE affords a complete vary of providers, from design help and materials choice to CAM programming and high quality management, offering a one-stop resolution for drone producers.

Furthermore, XMAKE has a workforce of skilled engineers and machinists who’re well-versed within the newest CNC machining methods. This experience permits them to optimize the manufacturing course of, scale back lead instances, and decrease materials wastage.

Moreover, XMAKE is dedicated to steady enchancment and innovation, guaranteeing that it stays on the forefront of CNC machining expertise.

Conclusion.

In conclusion, CNC machining affords a extremely efficient resolution for enhancing drone body manufacturing effectivity. By implementing methods resembling design for manufacturability, high-speed machining, multi-axis machining, automated software changers, superior CAM software program, and materials optimization, producers can considerably scale back manufacturing instances, decrease materials wastage, and guarantee excessive precision and high quality of their drone frames.

As a number one CNC machining provider, XMAKE offers a spread of superior CNC manufacturing processes tailor-made to the wants of drone producers. Their state-of-the-art gear, skilled workforce, and complete providers make them an excellent companion for any firm seeking to improve their drone body manufacturing effectivity.

By leveraging the facility of CNC machining and partnering with a dependable provider like XMAKE, drone producers can keep aggressive in a fast-paced and demanding market.

FAQs

1. What are drone frames product of?

Drone frames are generally product of supplies like carbon fiber for energy and lightness, aluminum for sturdiness, and generally plastics for cost-effectiveness and ease of molding.

2. How are drone frames measured?

Drone frames are measured by the diagonal distance between reverse motor mounts or the general size, width, and top. This helps in sizing parts and figuring out flight traits.

3. Are you able to 3D print drone frames?

Sure, you’ll be able to 3D print drone frames. It affords design flexibility, however the materials have to be robust sufficient. Nylon and a few high-strength filaments are sometimes used for 3D-printed drone frames.

Reference

1. https://hyperlink.springer.com/article/10.1007/s12206-024-1210-x

2. https://newbeedrone.com/merchandise/cockroach-82-brushless-super-durable-frame

3. https://www.dronetechplanet.com/how-to-build-a-drone-from-scratch-step-by-step-guide/

The submit Enhancing Drone Body Manufacturing Effectivity with CNC Machining Methods appeared first on XMAKE | Customized Components On-Demand Manufacturing.