CNC Machining for the Medical Trade: What You Must Know

Think about a robotic sculptor that carves steel or plastic into life-saving instruments—that’s medical CNC machining! CNC (Pc Numerical Management) makes use of computer systems to information machines in reducing supplies into actual shapes, like making synthetic joints or tiny surgical screws. In healthcare, medical CNC machining creates super-precise elements (assume smaller than a grain of rice!) that medical doctors depend on, resembling pacemakers or hip replacements. These machines work like super-skilled artists, turning blocks of fabric into protected, dependable instruments that preserve individuals wholesome. No errors, no guesswork—simply science making healthcare smarter!

Why is CNC machining used for the medical business?

Medical CNC machining is the spine of contemporary healthcare manufacturing, making certain instruments and gadgets work flawlessly contained in the human physique. Right here’s why it’s indispensable:

🩺 Precision Saves Lives

Medical CNC machining creates elements like spinal implants or coronary heart valve elements with tolerances tighter than 1/tenth a human hair. This accuracy ensures gadgets match completely throughout surgical procedures, lowering restoration time and issues. Even a tiny error might threat affected person security, so precision is non-negotiable.

🏥 Protected Supplies

The method works with biocompatible supplies like titanium (for joint replacements) and PEEK plastic (for non-toxic surgical instruments). These supplies received’t set off allergic reactions or corrode contained in the physique, holding sufferers protected long-term.

📜 Strict Guidelines

Hospitals require FDA and ISO 13485 certification for all gadgets. Medical CNC machining delivers an identical, defect-free elements in each batch, passing rigorous high quality checks and making certain compliance with life-saving requirements.

🔄 Customized Fixes

Sufferers usually want personalised options, like cranial plates formed to their cranium. CNC machines flip MRI/CT scan knowledge into customized 3D fashions, producing one-off elements shortly with out pricey molds.

🚀 Velocity = Survival

From prototyping ventilators to mass-producing syringe elements throughout pandemics, CNC machines work 24/7. This pace accelerates breakthroughs, getting essential instruments to medical doctors sooner.

💡 Clear & Sterile

CNC-machined elements have ultra-smooth surfaces, leaving no microscopic cracks the place micro organism might disguise. This simplifies sterilization, lowering an infection dangers in working rooms.

🌍 Much less Waste

Exact reducing minimizes uncooked materials waste—essential when utilizing costly alloys like cobalt-chrome. Much less scrap additionally means decrease prices and a smaller environmental footprint.

Limitations of CNC machining within the medical sector

Whereas medical CNC machining is transformative, it’s not with out constraints. Key challenges embody:

💰 Excessive Prices for Small Volumes

Customized implants or prototypes are dear resulting from setup and programming charges. Very best for mass manufacturing, however small batches pressure budgets.

🛠️ Design Complexity

Tiny, intricate elements (e.g., microfluidic chips) might have hybrid strategies like 3D printing, including steps and prices.

⚠️ Materials Challenges

Brittle biocompatible supplies (e.g., porous titanium) require pricey, specialised instruments and gradual machining speeds.

⏳ Regulatory Delays

FDA/ISO certifications and materials testing add weeks to timelines, delaying life-saving instruments.

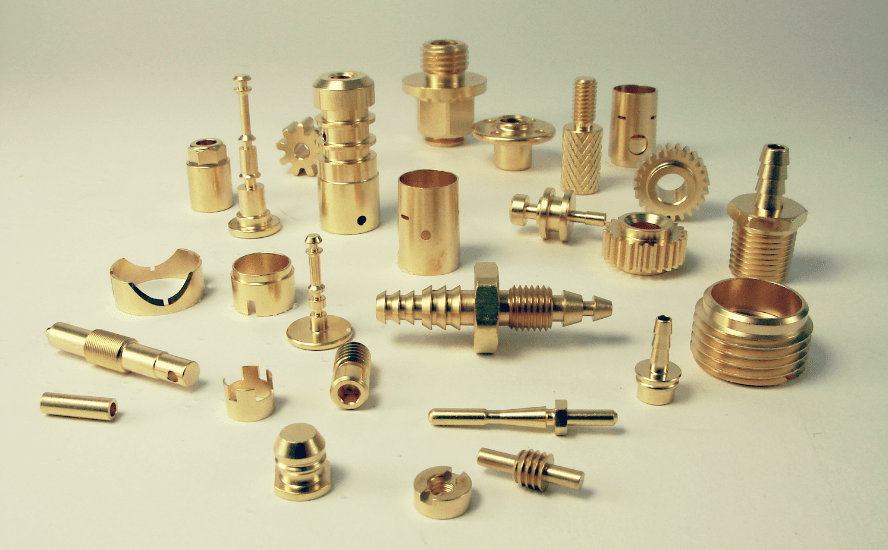

Widespread Supplies for Machined Medical Elements

| Materials | Compliance | Key Properties | Purposes |

|---|---|---|---|

| ASTM F67/F136 (implant-grade) | Excessive strength-to-weight ratio, corrosion resistant | Orthopedic prosthetics, cranial plates | |

| ASTM F138/F139 (surgical metal) | Yield power as much as 1,100 MPa, cost-effective | Scalpels, bone fixation screws | |

| ISO 10993-1 (biocompatibility) | Good tensile power, radiolucent | Spinal fusion cages, dental abutments | |

| ASTM F75/F1537 (solid/wrought implants) | Excessive put on resistance, fatigue power | Coronary heart valves, dental prosthetics | |

| ISO 13485 (non-implant gadgets) | Light-weight, anodizable floor | MRI elements, surgical robotics | |

| EN ISO 13356 (dental/orthopedic) | Excessive flexural power, low thermal conductivity | Dental crowns, cochlear implants |

Titanium (Grade 2, 5, 23)

- Compliance: ASTM F67/F136 (implant-grade).

- Key Properties: Excessive strength-to-weight ratio (450–950 MPa tensile power), osseointegration functionality, and corrosion resistance.

- Purposes: Orthopedic prosthetics, cranial plates, non-ferromagnetic surgical devices.

- Machining Word: Requires coated carbide instruments to handle warmth throughout reducing.

Stainless Metal (316L, 17-4 PH)

- Compliance: ASTM F138/F139 (surgical metal).

- Key Properties: Yield power as much as 1,100 MPa, glorious sterilizability, and cost-efficiency.

- Purposes: Scalpels, biopsy forceps, bone fixation screws.

- Machining Word: Low-carbon 316L minimizes carbide precipitation in heat-affected zones.

PEEK (Polyetheretherketone)

- Compliance: ISO 10993-1 (biocompatibility).

- Key Properties: Tensile power of 90–100 MPa, radiolucency, and elastic modulus akin to cortical bone.

- Purposes: Spinal fusion cages, arthroscopic device handles, dental abutments.

- Machining Word: Low thermal conductivity necessitates exact coolant management.

Cobalt-Chrome Alloys (CoCrMo)

- Compliance: ASTM F75/F1537 (solid/wrought implants).

- Key Properties: Put on resistance (HV 300–400), high-temperature stability, and fatigue power.

- Purposes: Synthetic coronary heart valves, dental prosthetics, load-bearing joint replacements.

- Machining Word: Diamond-coated instruments beneficial for hard-turning operations.

Aluminum (6061-T6, 7075-T6)

- Compliance: ISO 13485 (non-implant gadgets).

- Key Properties: Density of two.7 g/cm³, anodizable floor, and EMI/RF shielding functionality.

- Purposes: MRI machine elements, wheelchair frames, surgical robotics.

- Machining Word: Excessive-speed machining (15,000+ RPM) prevents materials galling.

Zirconia (Y-TZP Ceramics)

- Compliance: EN ISO 13356 (dental/orthopedic).

- Key Properties: Flexural power >1,000 MPa, low thermal conductivity, and bacterial adhesion resistance.

- Purposes: Dental crowns, cochlear implant housings, minimally invasive surgical instruments.

- Machining Word: Laser-assisted machining prevents micro-cracking.

Components that Affect the Alternative of Materials for Medical CNC Machining

Choosing the suitable materials for medical CNC machining is essential to making sure system security, performance, and regulatory compliance. Key issues embody:

🩺 Biocompatibility & Regulatory Compliance

- Supplies should meet ISO 10993-1/FDA requirements to make sure affected person security. Titanium and PEEK are FDA-approved for implants, whereas stainless-steel is restricted to non-implant instruments resulting from potential ion leaching.

⚙️ Mechanical & Machining Properties

- Energy, put on resistance, and machinability dictate feasibility. Instance: Cobalt-chrome’s hardness (HV 400) fits joint replacements however calls for diamond-coated instruments, elevating prices.

💰Price & Sustainability

- Excessive-cost alloys like titanium are justified for implants however prevented in disposable instruments. Recyclability (e.g., titanium’s 95% reuse fee) aligns with eco-friendly mandates.

📜 Regulatory Compliance

- FDA/ISO mandates dictate authorized supplies for particular purposes. Instance: PEEK is licensed for spinal implants (ASTM F2026) however not for load-bearing joints.

CNC Machining for Medical Gadget Purposes

Medical CNC machining is the unsung hero behind gadgets that preserve hearts beating, joints shifting, and diagnoses correct. Right here’s the way it powers 5 life-changing improvements:

1. Bone-Fusing Orthopedic Implants

Titanium knee replacements and spinal cages achieve their bone-like textures by means of CNC’s exact milling. This roughness helps human cells latch onto implants, turning overseas objects into pure physique elements over time.

2. Extremely-Sharp Surgical Devices

From laser-cut biopsy needles to anti-slip scalpel handles, CNC machines form stainless-steel into instruments surgeons belief. Mirror-like finishes forestall bacterial buildup, whereas ergonomic designs cut back hand fatigue throughout marathon operations.

3. Imaging-Protected Diagnostic Elements

MRI machines demand non-magnetic elements. CNC crafts aluminum radiofrequency coils and titanium affected person trays that vanish inside scanners, making certain clear pictures with out metallic “ghosts.”

4. Smile-Good Dental Restorations

Zirconia crowns emerge from CNC mills with 20µm accuracy—so lifelike, even dentists battle to identify them. Customized abutments and aligners are batch-produced in a single day, reducing wait occasions from weeks to days.

5. Bespoke Prosthetics & Exoskeletons

CNC converts 3D limb scans into carbon-fiber prosthetic sockets or robotic exo-joints. Sufferers seize espresso or climb stairs with gadgets molded to their distinctive musculature.

The best way to Select the suitable Producer for prototyping Medical Elements

Choosing a producer for medical CNC machining is like choosing a surgical companion—precision, belief, and compliance are non-negotiable. Right here’s your guidelines:

1. Certifications First

Guarantee they maintain ISO 13485 (medical system high quality) and FDA registration. These show they meet strict hygiene, traceability, and documentation requirements.

2. Materials Mastery

Search for expertise with biocompatible metals (titanium, stainless-steel) and plastics (PEEK, UHMWPE). Ask for take a look at certifications to substantiate materials purity.

3. Precision Pedigree

Confirm their machines obtain ±0.001mm tolerances or higher. Microscopic errors in prototypes can derail FDA approvals.

4. Prototyping Velocity

Demand a 1–2 week turnaround for preliminary samples. Delays in medical prototyping threat patent expirations or competitor strikes.

5. Publish-Processing Expertise

Examine if they provide medical-grade finishes:

- Electropolishing for burr-free edges.

- Passivation to forestall stainless-steel corrosion.

- Cleanroom packaging to keep away from contamination.

6. Regulatory Navigation

Select companions who pre-test elements for ISO 10993-5 (cytotoxicity) or ASTM F756 (materials biocompatibility). They need to flag compliance dangers early.

7. Case Research & References

Request examples of FDA-cleared gadgets they’ve prototyped, like insulin pumps or arthroscopic instruments. Name previous purchasers to vet reliability.

Think about Partnering with XMAKE

- Finish-to-Finish Assist: From design optimization to closing manufacturing.

- State-of-the-Artwork Machines: Newest 5-axis methods for complicated geometries.

- Trade-Confirmed Outcomes: Trusted by leaders in aerospace, vitality, and past.

Don’t let complicated initiatives stall innovation—Contact XMAKE Right now to debate your subsequent problem. Let’s engineer the longer term, collectively!

Associated put up you could curiosity

1.Every little thing You Ought to Find out about Swiss CNC Machining in 2025|XMAKE

2. 9 Purposes of Plastic Injection Molding for Medical Gadgets in 2024

3. 10 Purposes of Metallic Injection Molding in Medical Gadgets in 2024

FAQ

Q. What’s the Swiss Machining Course of?

Swiss machining is a precision manufacturing methodology the place a sliding headstock and information bushing stabilize lengthy, slender workpieces as rotating instruments lower complicated geometries. Developed for watchmaking, it excels at producing small, intricate elements (e.g., medical screws, drone sensors) with tolerances as much as ±0.0001″. In contrast to conventional lathes, Swiss machines transfer the fabric axially whereas instruments function radially, enabling high-volume manufacturing of micro-components in a single setup.

Q. How Do I Choose the Proper Swiss CNC Lathe?

Think about these components:

- Half Measurement: Select machines with information bushings matching your workpiece diameter (sometimes 0.5–32mm).

- Materials: Go for high-torque spindles for onerous metals (titanium) or coolant methods for plastics.

- Quantity: Prioritize bar feeders and automation for mass manufacturing.

- Complexity: Search for dwell tooling (milling/drilling) and sub-spindles for multi-step operations.

- Finances: Entry-level Swiss lathes begin at $150k; superior fashions with Y-axis or robotics exceed $500k.

Q. What Supplies Are Utilized in Swiss Machining?

Widespread supplies embody:

- Metals: Stainless-steel (medical instruments), titanium (aerospace fasteners), brass (connectors).

- Plastics: PEEK (implants), Delrin (gears), Ultem (insulators).

- Exotics: Inconel (jet engines), Nitinol (stents), zirconia (optical elements).

Swiss CNC machining handles brittle or heat-sensitive supplies by way of low-vibration reducing and exact coolant supply.

Referenes

1. Altintas, Y. (2012). Manufacturing Automation: Metallic Slicing Mechanics, Machine Software Vibrations, and CNC Design. Cambridge College Press.

Covers Swiss machining ideas, toolpath optimization, and vibration management.

2. ISO 10791-7:2020. Check Circumstances for Machining Facilities – Accuracy of Completed Check Items.

Standardizes Swiss CNC machine efficiency metrics for micro-parts.

3. AMT – Affiliation for Manufacturing Expertise. (2023). International Swiss-Kind Lathe Market Evaluation.

Particulars adoption tendencies in medical, aerospace, and automotive sectors.

4. J. Med. Gadgets. (2021). Precision Machining of Titanium Spinal Implants. ASME.

Case research on Swiss CNC’s position in FDA-compliant medical gadgets.

5. ASM Handbook Vol. 16. (2015). Machining of Excessive-Energy Alloys and Plastics. ASM Worldwide.