On the planet of commercial manufacturing, the extruder gearbox stands as a linchpin in varied manufacturing processes. For those who’re concerned in plastics, meals, or rubber manufacturing, you’re probably acquainted with the significance of easy and environment friendly extrusion.

Nevertheless, many would possibly discover themselves grappling with questions on this significant part. What precisely is an extruder gearbox? How does it operate, and what varieties can be found?

This text goals to demystify these points, offering you with a complete understanding to make knowledgeable choices relating to your manufacturing operations.

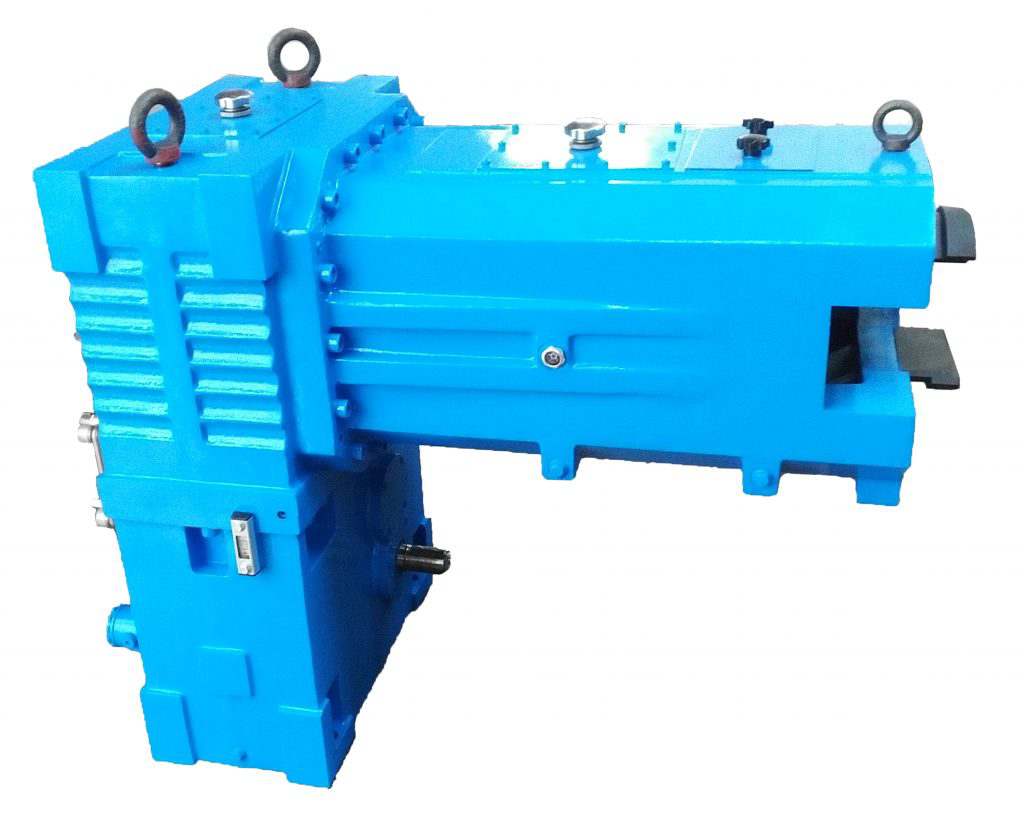

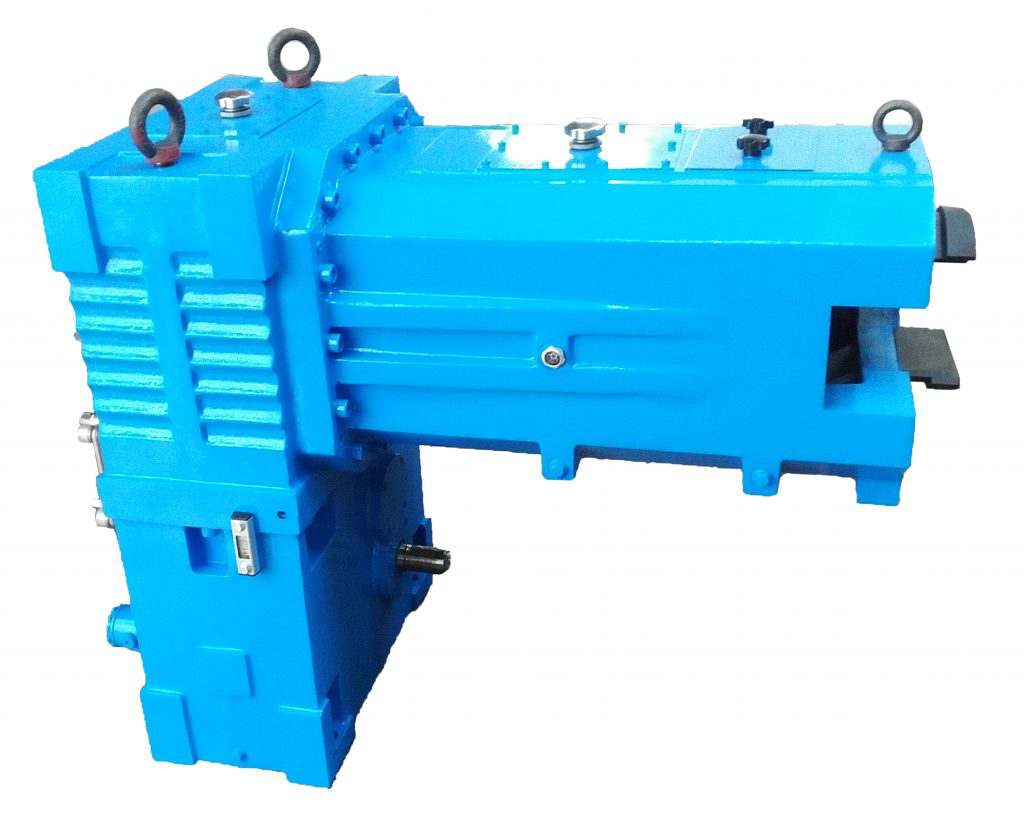

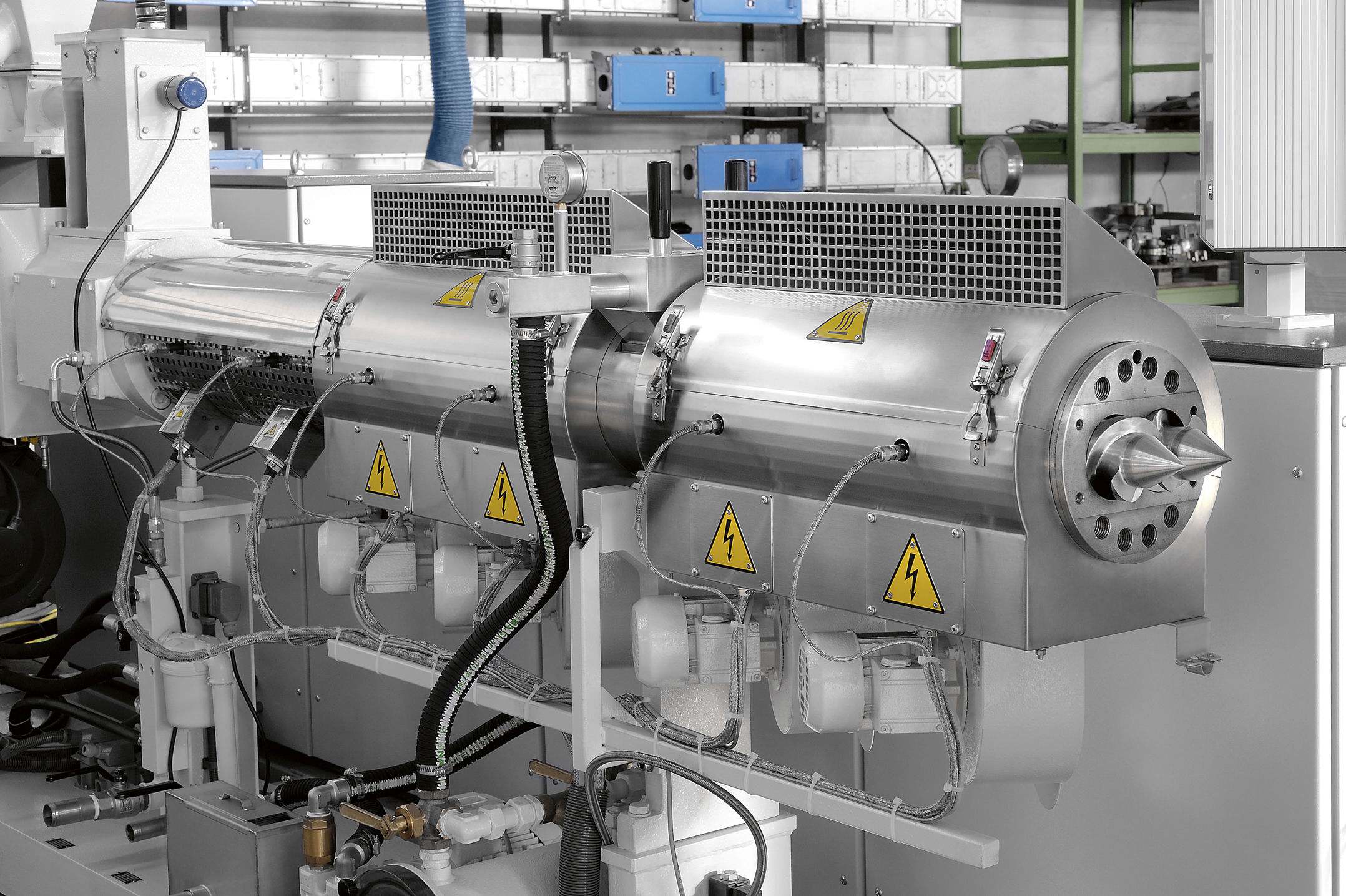

An extruder gearbox, merely put, is a mechanical gadget designed particularly for an extruder machine. It serves as a bridge between the ability supply, sometimes an electrical motor, and the extruder screw.

Its main function is to change the velocity and torque output from the motor to satisfy the necessities of the extrusion course of. Identical to a transmission in a automobile, it ensures that the ability is transferred successfully to drive the extruder screw, which in flip pushes and shapes the uncooked supplies by means of the die.

In essence, the gearbox for the extruder machine is an important a part of the extrusion system, enabling exact management over the extrusion course of.

The operation of an extruder gearbox is predicated on the precept of substances discount. When the motor begins, it rotates at a excessive velocity with comparatively low torque. The gearbox steps in to scale back this excessive velocity and enhance the torque.

Contained in the gearbox, a sequence of gears mesh collectively. Because the enter shaft related to the motor turns, it drives the primary set of gears. These gears, in flip, have interaction with different gears within the gearbox, steadily lowering the velocity of rotation. The output shaft, which is related to the extruder screw, then rotates at a a lot slower velocity however with considerably larger torque.

This high-torque output is what permits the extruder screw to successfully push and course of the uncooked supplies by means of the extrusion die, whether or not it’s molten plastic, dough, or rubber compound.

Gears are the center of the extruder gearbox. They arrive in several varieties, corresponding to helical, spur, and worm gears. Helical gears are in style attributable to their easy operation and excessive – load-carrying capability.

Their angled enamel have interaction steadily, lowering noise and vibration. Spur gears, alternatively, are easier in design and are sometimes utilized in functions the place value is a significant component. Worm gears, with their distinctive screw-like form, are identified for his or her excessive discount ratios and self-locking capabilities in some instances.

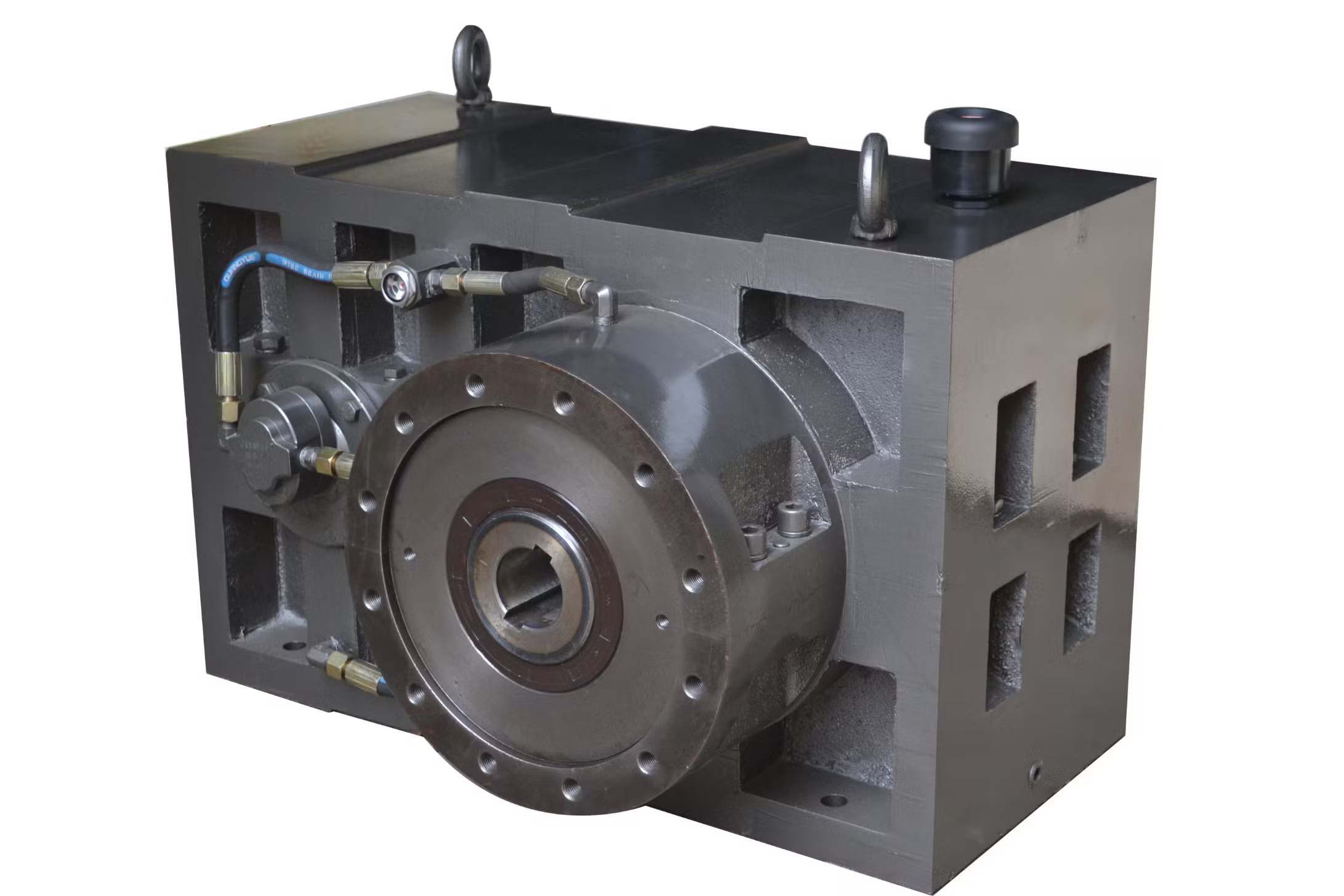

The shafts in an extruder gearbox are liable for transmitting the ability from one set of gears to a different and finally to the extruder screw. They have to be robust sufficient to face up to the torque and forces generated throughout operation.

The enter shaft connects to the motor, whereas the output shaft is linked to the extruder screw. Intermediate shafts may additionally be current to assist and switch energy between completely different gear phases.

Bearings play a vital function in lowering friction between the rotating components of the gearbox. They assist the shafts and permit them to rotate easily. Several types of bearings, corresponding to ball bearings and curler bearings, are used relying on the load necessities and working situations of the gearbox.

The housing of the extruder gearbox encloses and protects all the inner parts. It offers a inflexible construction to maintain the gears and shafts in correct alignment. The housing is often product of high-strength supplies like forged iron or metal to face up to mechanical stresses and make sure the long-term reliability of the gearbox.

The gearbox is crucial in extrusion processes for a number of causes. Firstly, it allows exact management of the extruder screw’s velocity. Completely different extrusion processes require completely different screw speeds to attain the specified product high quality.

For instance, in plastic movie extrusion, a selected screw velocity is required to make sure uniform thickness. The gearbox permits for simple adjustment of this velocity. Secondly, the gearbox considerably will increase the torque. Extruding supplies typically require a considerable amount of power to push them by means of the die. The gearbox’s potential to multiply torque ensures that the extruder screw has sufficient energy to deal with the viscous resistance of the uncooked supplies.

With no correctly functioning gearbox, the extrusion course of may end in inconsistent product high quality, diminished manufacturing effectivity, and even injury to the extruder.

What are the Variations Between the Customary Gearbox and Extruder Gearbox?

Helical gearboxes are a well-liked alternative in extruder functions. Their key attribute is the angled enamel of the gears. As talked about earlier, this design leads to easy operation.

The angled enamel have interaction steadily, lowering affect forces and minimizing noise and vibration. That is significantly vital in extrusion processes the place easy materials move is essential for product high quality.

Helical gearboxes even have a excessive – load-carrying capability. They’ll deal with the numerous torque required to drive the extruder screw, making them appropriate for large-scale extrusion operations.

Parallel shaft gearboxes function shafts which are parallel to one another. This design permits for a comparatively easy and compact format. They differ from different varieties in that the ability is transmitted between parallel shafts utilizing gears.

Parallel shaft gearboxes are identified for his or her effectivity in energy transmission. They’ll obtain excessive discount ratios whereas sustaining an excellent degree of mechanical effectivity. In extrusion, such a gearbox can be utilized in functions the place area is a constraint, however high-torque transmission continues to be required.

Worm gearboxes have a singular design the place a worm (a screw-like gear) meshes with a worm wheel. One of many principal benefits of utilizing worm gearboxes in extrusion is their excessive discount ratio. They’ll obtain a major discount in velocity with only one or a couple of gear phases.

That is helpful in functions the place a big velocity discount is required, corresponding to in some specialised plastic extrusion processes. Moreover, worm gearboxes can present self-locking performance in sure conditions.

Which means that as soon as the extruder screw is in a selected place, it may be held in place with out extra braking mechanisms, which will be useful in some extrusion operations.

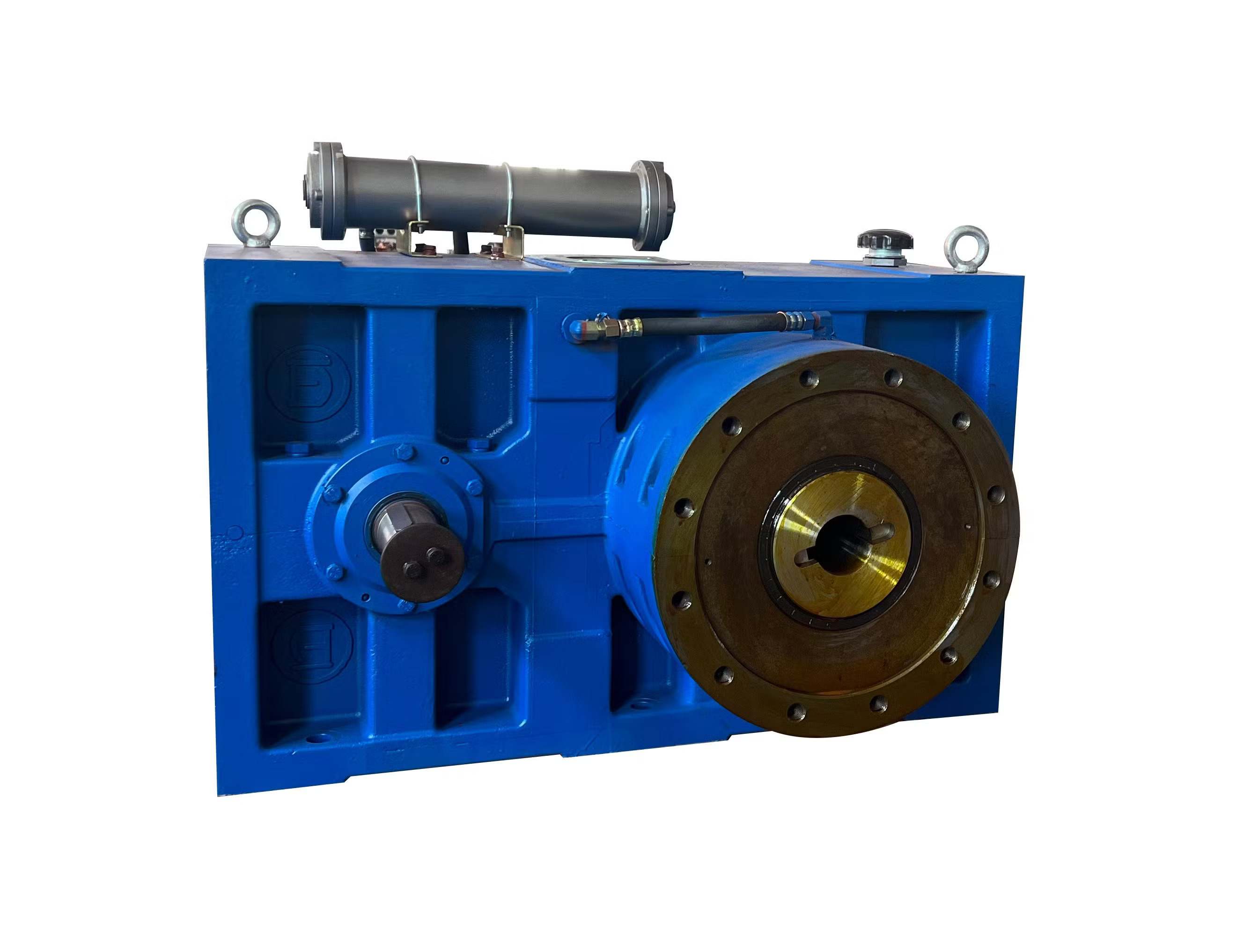

Planetary gearboxes include a central solar gear, a number of planet gears, and an outer ring gear. When do you have to select a planetary gearbox to your extruder?

Planetary gearboxes are extremely environment friendly and might deal with high-torque hundreds in a compact design. They’re appropriate for functions the place area is proscribed, however high-performance torque transmission is required.

In extrusion, they can be utilized in high-speed extrusion traces the place exact velocity management and high-torque output are essential. The multiple-planet gears distribute the load evenly, lowering put on and rising the lifespan of the gearbox.

Torque and Pace Adjustment

Extruder gearboxes have a direct affect on torque and velocity. As talked about earlier than, they cut back the high-speed output of the motor and enhance the torque. This adjustment is important for the extrusion course of.

For instance, if the motor rotates at 1500 RPM with a certain quantity of torque, the gearbox can cut back the velocity to, say, 50 RPM whereas rising the torque several-fold. This low-speed, high-torque output is what allows the extruder screw to successfully push the uncooked supplies by means of the die.

Completely different extrusion processes could require completely different torque-speed mixtures, and the gearbox permits for these changes to be made.

The gearbox performs a significant function in energy transmission. It takes the mechanical energy from the motor and transfers it to the extruder screw. The gears contained in the gearbox make sure that the ability is transmitted effectively with minimal losses.

The right meshing of the gears and the standard of the supplies used within the gearbox parts contribute to the effectiveness of energy transmission. Any inefficiencies in energy transmission can result in power waste and diminished productiveness within the extrusion course of.

Gearboxes contribute considerably to the effectivity of the extrusion course of. By offering the precise torque and velocity, they make sure that the extruder screw operates at its optimum efficiency degree.

A well-designed gearbox can cut back power consumption by minimizing energy losses through the speed-torque conversion. It additionally helps in sustaining a constant extrusion price, which is essential for producing high-quality merchandise.

For example, in meals processing extrusion, a constant extrusion price ensures that the ultimate meals merchandise have a uniform form and texture.

Within the plastics business, extruder gearboxes are utilized in a variety of functions. They’re essential in plastic pipe extrusion, the place the gearbox offers the required torque to push the molten plastic by means of the die to type pipes of various diameters and thicknesses.

In plastic movie extrusion, the gearbox allows exact management of the screw velocity, which is important for reaching the specified movie thickness. Moreover, in plastic profile extrusion, the gearbox ensures easy and constant extrusion of advanced plastic shapes.

Within the meals processing business, extruder gearboxes improve the manufacturing course of in a number of methods. For instance, in pasta manufacturing, the gearbox drives the extruder screw to push the dough by means of the die, creating varied pasta shapes.

The gearbox permits for exact management of the dough’s move price, making certain constant pasta high quality. In snack meals extrusion, the gearbox helps in processing the uncooked supplies into completely different snack shapes by offering the correct amount of torque and velocity to the extruder screw.

Rubber and Polymer Functions

In rubber and polymer functions, extruder gearboxes are used to course of rubber compounds and polymers. In rubber extrusion, the gearbox allows the extrusion of rubber merchandise corresponding to hoses, seals, and tires.

It offers the excessive torque wanted to deal with the viscous rubber supplies. In polymer processing, the gearbox helps in shaping polymers into completely different varieties, corresponding to sheets, rods, and filaments.

When deciding on the precise gearbox, a number of specs are important. The discount ratio is a key issue. You could decide the required velocity discount primarily based on the motor velocity and the optimum screw velocity to your extrusion course of.

The torque capability of the gearbox must also be fastidiously thought-about. It should be capable to deal with the utmost torque necessities of the extruder screw beneath regular and peak working situations. Moreover, the enter and output shaft sizes, in addition to the kind of shaft connection, must match the motor and the extruder screw.

Load necessities have a major affect on gearbox choice. Completely different extrusion processes have completely different load profiles. For those who’re extruding high-viscosity supplies, you’ll want a gearbox with the next torque-handling capability.

The load may additionally range relying on the manufacturing price. Greater manufacturing charges could end in elevated hundreds on the gearbox. It’s vital to decide on a gearbox that may deal with these load variations with out sacrificing efficiency or sturdiness.

Upkeep Issues

Upkeep is a vital facet when selecting an extruder gearbox. Some gearboxes could require extra frequent lubrication or part replacements. You must contemplate the accessibility of the inner parts for upkeep.

A gearbox with simply detachable covers and parts could make upkeep duties, corresponding to gear inspection and bearing alternative, a lot simpler. Moreover, the provision of spare components and the benefit of acquiring them must also be taken under consideration.

Automation is having a serious affect on extruder gearbox design. With the rising development in direction of automated manufacturing, gearboxes are being designed to be extra appropriate with automated management methods.

This contains options corresponding to sensors that may monitor the gearbox’s efficiency in real-time, corresponding to temperature, vibration, and torque. The info from these sensors can be utilized to optimize the operation of the gearbox and your complete extrusion course of.

For instance, if the temperature of the gearbox exceeds a sure restrict, the management system can regulate the velocity or take different corrective actions to forestall injury.

Developments are being made within the supplies used for gearboxes. New supplies are being developed to enhance the energy, sturdiness, and put on resistance of gearbox parts.

For example, superior alloys and composite supplies are being explored. These supplies can stand up to larger temperatures and hundreds, lowering the necessity for frequent part replacements. In addition they contribute to the general effectivity of the gearbox by lowering friction and power losses.

Power Effectivity and Sustainability

Power effectivity and sustainability tendencies are additionally affecting gearbox growth. Producers are specializing in designing gearboxes that devour much less power.

This may be achieved by means of improved gear designs, higher lubrication methods, and extra environment friendly energy transmission. Moreover, there’s a rising emphasis on utilizing sustainable supplies and manufacturing processes.

For instance, some gearboxes at the moment are being constituted of recycled supplies, and the manufacturing processes are being optimized to scale back waste and environmental affect.

This course of permits for exact shaping of the housing from uncooked steel blocks, making certain correct match and alignment of inner parts. The housing’s advanced shapes and holes for shafts, bearings, and lubrication will be precisely created.

Gears are sometimes manufactured utilizing CNC gear hobbing. This technique cuts the gear enamel with excessive precision, following the precise tooth profile required for the gearbox design.

After hobbing, CNC grinding could also be employed to additional refine the gear enamel, bettering their floor end and accuracy. This reduces friction and enhances the gear’s efficiency and lifespan.

Bearings, though typically sourced from specialised producers, may additionally endure some CNC-assisted ending processes to make sure an ideal match throughout the gearbox.

These CNC manufacturing processes work collectively to provide extruder gearboxes that meet the high-performance and reliability necessities of contemporary extrusion processes.