That is going to harm.

With tariffs set in place by President Trump in opposition to Mexico and Canada, and expanded tariffs being levied in opposition to China, there’s completely no disagreement that customers and producers will really feel rapid ache within the type of elevated costs.

The unknown is how a lot reduction might be realized as soon as the fallout from these financial sanctions normalizes. Ideally, U.S. producers will profit from an excellent enjoying area throughout business-to-business and retail environments – permitting them to develop and improve the hiring of staff at larger wages.

Placing the politics of the state of affairs apart, there are a variety of key questions that must be answered:

- How a lot will prices improve?

- Will manufacturing be capable to take up the rapid worth will increase and nonetheless have the flexibility to put money into the assets wanted to improve manufacturing and re-organize provide chains?

- With a NAM-estimated 428,000 unfilled manufacturing jobs, does the workforce capital exist that can enable U.S. producers to reshore or develop operations to satisfy tariff-based provide chain changes?

- Will retaliatory tariffs negate any of the particular or potential positive factors sought by these initiatives?

Provide chain, finance and commerce specialists from the industrial sector lately provided their views on what to anticipate and the way to reply.

Ben Johnston, COO of Kapitus: “Tariffs of this significance might, over time, make manufacturing within the U.S. extra financial relative to importing items from overseas, which could possibly be good for some industries.

“However within the quick to medium time period, these tariffs are seemingly to drive inflation considerably larger and trigger important disruption to the international provide chain, threatening many U.S. jobs at producers, wholesalers and retailers. Increased tariffs will definitely trigger costs to rise for U.S. customers. This is not going to solely spur inflation however will decrease general consumption, slowing the financial system.

“Nonetheless, in the long term, larger tariffs could assist defend the viability of sure U.S. producers and will incent larger funding in U.S. manufacturing. Whereas this is able to be a constructive for some sectors of the financial system, the impression of tariffs is tough to foretell as we are able to anticipate U.S. exports to impacted nations to be struck by retaliatory tariffs, lowering demand for items produced within the U.S. and offered overseas.”

Seth Weisblatt, Director, TrueCommerce: “With a lot uncertainty surrounding tariffs, the finest strategy is to give attention to growing mitigation methods that protect flexibility and resilience. This contains maintaining contracts quick, sustaining diversified provider relationships, and safeguarding money circulation.

“Drawing from classes discovered throughout the COVID-19 shutdowns, companies ought to prioritize managing stock rigorously and making certain liquidity to climate potential disruptions. Whereas worth changes, when vital, can function a short-term measure to maintain profitability, they need to be considered as one part of a broader technique, not as a reactionary step. “

Simon Kim, CEO and Founding father of Glassdome: “Even when aluminum producers and producers do not go the total price on to their clients, it might nonetheless be a stunning jolt for individuals from all walks of life, from aerospace executives taking a look at engine elements to households on the {hardware} or grocery retailer. Merchandise like soda cans, home equipment and vehicles comprise a lot of tariffed metals. Everybody says they need American-made merchandise, after which they choose cheaper overseas alternate options when it comes time to swipe the credit score card.

“The American metal and aluminum industries have been battling larger working prices than worldwide rivals for years, and that is with out moving into points like Chinese language firms dumping state-backed metal overproduction for pennies on the yuan.

“Automating manufacturing can assist to a level, nevertheless it will not clear up each downside related to an costly and getting old manufacturing labor pool. Many producers are struggling to search out high quality staff. If that scarcity of certified, or simply able to be educated, staff cannot sustain with elevated orders, costs will keep excessive.

“In the long term, the tariff on metal and aluminum might be a constructive power. If we put money into coaching a brand new manufacturing workforce and constructing a newly strengthened home manufacturing base. It might particularly profit these ‘left behind’ areas which were such a spotlight for each Trump and Biden.”

Vinny Licata, Director of Logistics, Fictiv: “It appears we’re heading into provide chain disruptions paying homage to 2020. Though the specifics could differ, the results on manufacturing are seemingly substantial, particularly for firms that rely closely on a single area for manufacturing.

“This may most likely lead to rising costs for sure shopper items, notably these tied to imports or uncooked supplies. Objects like vehicles, electronics, and clothes. Manufacturing prices are additionally set to rise, particularly for companies counting on supplies from nations focused by Trump’s tariffs. Corporations utilizing tariffed metal or aluminum will face larger materials prices, which might result in diminished earnings, decreased funding, or even the necessity to relocate manufacturing.

“Superior manufacturing ought to be a consideration because it might result in efficiencies that may not totally take up the tariff impression however might assist keep pricing. It is going to be vital that companies watch out about making snap provide chain choices centered solely on tariffs. Corporations should give attention to long-term strategic investments and perceive that geopolitical change will happen. Provide chain resilience might be the secret over the following 4 years.”

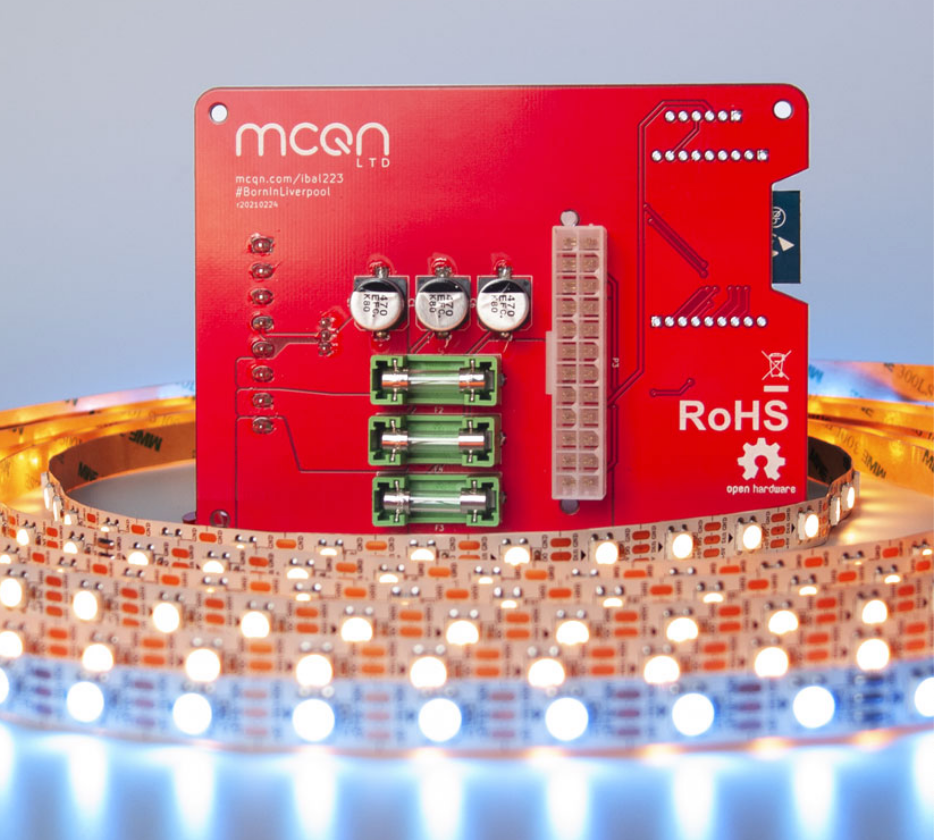

Oshri Cohen, CEO, Cybord: “The tariffs imposed by the Trump administration are a wake-up name to the manufacturing trade, and in the event that they aren’t paying consideration, they need to be. These tariffs will create short-term confusion and chaos within the electronics provide chain globally, shining a highlight on the present lack of transparency in materials sourcing and the pervasive disconnect between the place elements really come from and what’s listed on the invoice of supplies.

“In the long term, these tariffs will power the trade to prioritize traceability to insulate itself from the various dangers of sourcing unauthorized, counterfeit, or tampered with digital elements and different supplies. As soon as the trade meets this pressing clarion name, the tide will increase all boats.”

Matt Lekstutis, Director, Efficio: “Corporations reliant on manufacturing unit manufacturing will face larger capital expenditure prices when buying or sustaining equipment. Producers could want to extend product costs to offset rising equipment prices or delay manufacturing unit upgrades, affecting manufacturing effectivity and competitiveness.

“We are going to seemingly see larger pricing in shopper items as a direct results of the rise in uncooked supplies. Improve in these prices might probably result in lack of jobs, closures of producing websites, and elevated offshoring, primarily to APAC. We’ll seemingly seeing a rise within the inflation fee.

“There’s a potential for the nations which can be affected by the tariffs might retaliate with counter tariffs, additional straining relations with international allies.”

Darcy MacClaren, Chief Income Officer, SAP Digital Provide Chain: “As tariffs dominate discussions amongst international political leaders, companies are going through elevated uncertainty of their provide chains. Tariff hikes add one other layer of complexity to an already unstable commerce surroundings.

“Expertise can play a key position in mitigating these impacts by offering real-time visibility. Within the quick time period, leveraging predictive algorithms to cut back uncertainty will higher place all industries for potential market instability.

“Within the mid to long run, companies could search alternate suppliers and can discover it more and more helpful to put money into provide chain options that join logistics information and suppliers on a worldwide scale, creating a extra cohesive and agile community. As coverage shifts proceed, leveraging know-how to trace compliance and assist sustainability claims might be essential.”

Phil Gulley, Co-Founder and Chief Technique Officer, Cofactr: “The newly imposed tariffs—and the uncertainty of what’s subsequent—have compelled U.S. producers into an advanced place.

“Within the quick time period, U.S. producers which have spent years streamlining their operations and dealing with vetted suppliers to distribute back-office processes and sourcing challenges, at the moment are compelled to prioritize optionality and push for visibility into tiered provide chains to know their publicity to overseas markets.

“When doable, they’re diversifying their suppliers, evaluating tariff mitigation methods, and strengthening relationships with current distributors to counteract worth adjustments, and are being compelled to shortly construct up their provide chain resilience to allow them to derisk manufacturing interruption. Many producers have additionally had an instantaneous response to stockpile assets, which has created a problematic cycle of provide and demand.

“Within the long-term, many producers wish to onshoring, however making that transition throughout all manufacturing classes and materials sourcing is neither fast nor practical contemplating the deep reliance on the worldwide provide chain. The fact is that shifting and scaling manufacturing in new areas, even within the U.S., can take a long time.

“For industries like medical know-how, shopper electronics and automotive, sure suppliers can’t get replaced, leaving companies with no selection however to soak up larger prices or go them on to customers. These complicated challenges might result in existential challenges and threats for some product strains.”

Kerrie Jordan, Group Vice President, Product Administration at Epicor: “Distributors which can be going to have the ability to climate the potential impression of deliberate tariffs will must be versatile and adaptable of their strategy to provide chain disruption. A part of this strategy entails leveraging applied sciences that present larger predictability and visibility inside their organizations.

“Distributors additional alongside on their cloud journeys and AI adoption will be capable to adapt extra shortly to potential disruptions. Over the previous two to 3 years, extra distributors have taken on some mild manufacturing to supply higher service to clients. People who have, are forward of the sport, and this might assist carry added resilience to their provide chain.

“If larger tariffs go into impact, imported items will price extra. Corporations should assess the impression of upper costs and create resilient methods to soak up, offset, or scale back the impression of upper prices. Corporations that manufacture domestically may have to extend output in the event that they expertise larger demand in native markets. Since they already manufacture in-country, they might have a leg up competitively, however they need to proceed to speculate to extend throughput, empower their staff, drive efficiencies and unlock insights for steady enchancment.”